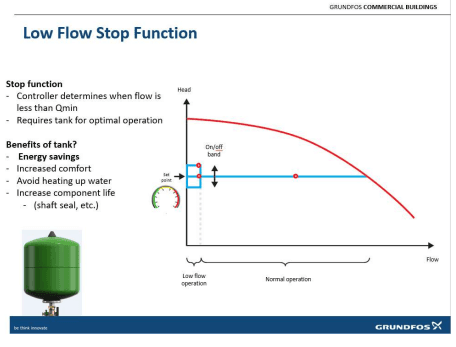

According to ASHRAE 90.1, Domestic Water Booster Systems must shut down during periods of no flow demand. Operating pump systems when there is little or no demand wastes energy and increases wear and tear on the pump and piping system. While this sounds simple, it is one of the most challenging control sequences for a Booster System.

Domestic Water Booster Systems are used to supply water to commercial buildings to be used in restrooms, kitchens, and to make up water to Hydronic Systems like Cooling Towers. The demand for water will change throughout the day and the pump system must be able to respond to these changes. In commercial office buildings, for example, there can be long periods of little or no water demand overnight when the building is empty or even in the middle of the afternoon when the building is occupied.

For a pump system to perform a low-flow shutdown, it must first be able to measure the flow demands in the system. Flow Switches and Flow Meters are mechanical means of measuring flow, which can work, but both require proper installation in the system piping for proper readings. Space and piping constraints can limit the installation of switches or flow meters.